The Uyghur Forced Labor Act and Your Supply Chain

The Uyghur Forced Labor Act and Your Supply Chain

Guest column by Tanya Arnt, WTC Denver

The Uyghur Forced Labor Prevention Act (UFLPA) came into effect a little over a year ago– on June 21, 2022, with the aim of preventing companies from profiting from products manufactured using forced labor from the Xinjiang Uyghur Autonomous Region (XUAR). Companies that operate in the United States must comply with the provisions of the UFLPA, as failure to do so may result in significant legal and financial penalties, including fines, import bans, and other sanctions.

What is UFLPA?

The Uyghur Forced Labor Prevention Act (UFLPA) requires Customs and Border Protection (CBP) to apply a presumption that imports of all merchandise mined, produced, or manufactured wholly or in part in Xinjiang, China, or by entities identified on the “UFLPA Entity List,” are presumed to be made with forced labor and are prohibited from entry into the United States under Section 307 of the Tariff Act of 1930.

The presumption applies unless the Commissioner of U.S. Customs and Border Protection (CBP) determines, through clear and convincing evidence, that the goods, wares, articles, or merchandise were not produced using forced labor or that UFLPA does not apply to the goods, wares, or merchandise seeking to be entered into the United States.

Three main reasons why every manufacturer should pay attention to the UFLPA even if they believe they are not impacted.

First and foremost, the reach of this law extends beyond regional boundaries. Even if your manufacturing processes are situated outside Xinjiang or even China, materials sourced from Xinjiang can inadvertently find their way into the production lines, even if your operations are based elsewhere. Xinjiang is a central hub for world market raw materials, and thereby numerous industries are unavoidably linked with Uyghur forced labor. Xinjiang is accountable for producing 20% of the world’s cotton, 40% of global polysilicon supplies utilized in solar panels, and 13% of the planet’s wind turbine output. In addition, 25% of tomato paste, 11% of walnuts, and 10% of the global rayon output have their origins in Xinjiang. From June 2022 to August, 2023, the U.S. Customs and Border Protection (CBP) stopped more than 5,059 shipments. Only 13% of these shipments by value originated in China; 60% came from Malaysia and 24% from Vietnam.

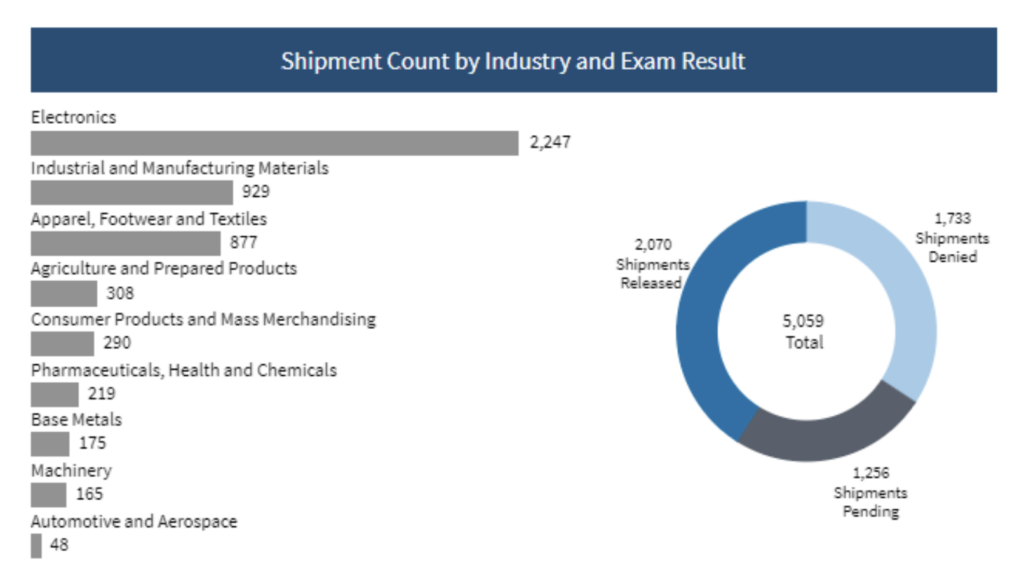

Second, wide industry impact. While specific industries such as cotton, tomato products, and polysilicon have been officially recognized as high-risk sectors under the act, its influence extends well beyond these defined boundaries. Below are the statistics from the CBP on the shipment count by industry:

In addition, it is also not only the industry and a product that need to be assessed, it is also the entities that are involved. Some of these entities are located in various parts of China, not in Xinjiang, and they also might manufacture different types of products that are not related to these industries. A list of entities in Xinjiang that mine, produce, or manufacture wholly or in part any goods, wares, articles and merchandise with forced labor can be found here.

Third, proving compliance. The law puts the burden of proof on manufacturers and importers to provide “clear and convincing evidence”, that the goods, wares, articles, or merchandise were not produced using forced labor or that UFLPA does not apply to the goods, wares, or merchandise seeking to be entered into the United States.

What should manufacturers do?

To address the implications of the UFLPA, manufacturers and importers should adopt a proactive approach that mitigates risk and ensures compliance. Below are best practices to follow:

- Transparent Supply Chains:Study your supply chain, all the way to the raw material level and continue through all tiers of the manufacturing process. Transparency helps find potential issues early.

- Thorough Audits: Regularly audit suppliers to ensure ethical standards. Check risks, visit sites, and interview workers to verify human rights adherence.

- Third-Party Validation:Get outside experts to assess your supply chain. Their independent review adds credibility.

- Supplier Code of Conduct: Implement clear guidelines for suppliers on ethical practices. Zero tolerance for forced labor should be emphasized, with clear consequences for violations.

- Detailed Documentation: Keep records of transactions and supply chain documents. These prove compliance. The documentation includes: supply chain documentation that demonstrates the country of origin and its components – packing list, bill of lading, documentation related to the payment and transportation of Raw Materials – invoices, contracts, purchase orders, proof of payment, documentation demonstrating the parties participating in the transaction.

In conclusion, the Uyghur Forced Labor Prevention Act is significant. By taking practical steps, manufacturers and importers can navigate challenges, lower risks, and adhere to ethical, legal, and reputation-based requirements.